TECHNOLOGY

Redefining Filtration: Our Design...

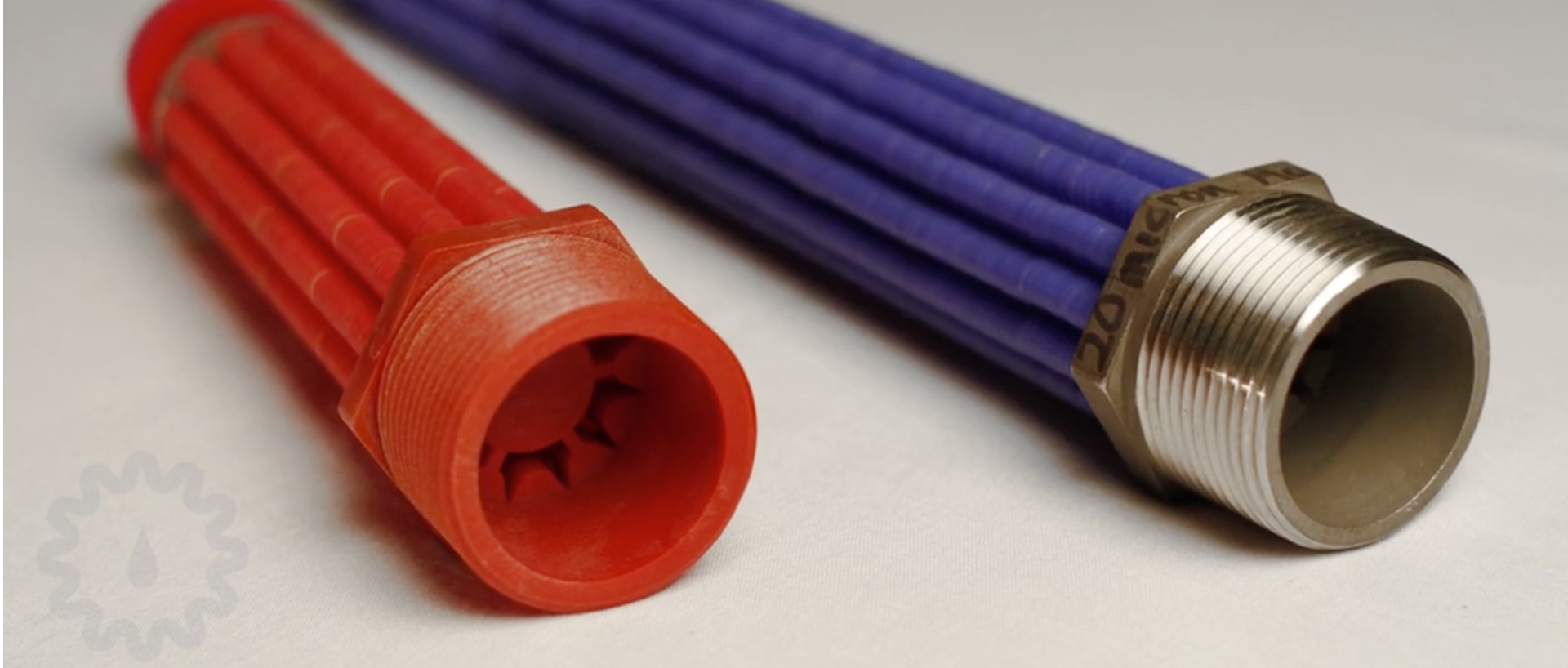

Our automatic self-cleaning filtration systems are both cost-effective and environmentally friendly. The key to our system’s superior perfomance lies within the patented Filtrex wafer-and-candle system.

Our Filtrex disc filters boast a number of advantages over other filtration media, including a higher open ratio, allowing optimal flow over a smaller surface area. Depending on the application, each wafer has up to two thousand microgrooves etched on each of its arched surfaces, allowing for precise filtration and maximum utilization of the wafer’s surface area. Barring abnormal applications, the thermoplastic wafers are permenantly re-usable, which means no costly throw-away media like cartridges or paper, and no harm done to the environment. They have the ability to self-clean during the automatic backwash cycle which minimizes system maintenance.

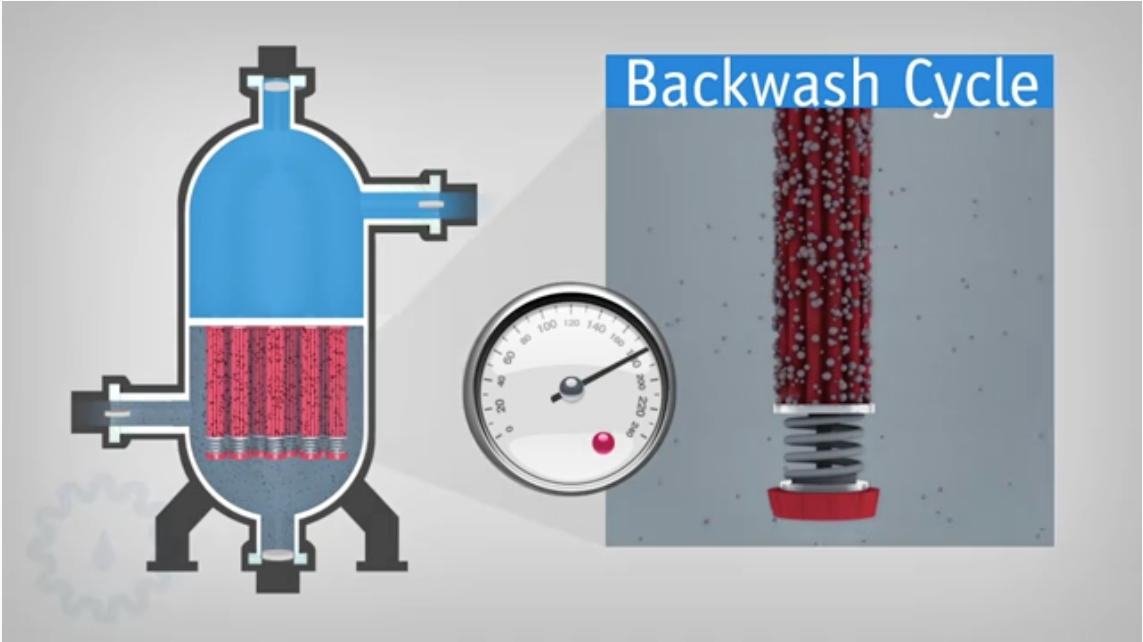

Backwash Cycle: How it Works...

Depending on the application, the Filtrex candles are grouped into a vessel, which contain anywhere from a single candle to as many as several hundred. The vessels consist of an upper and lower chamber. During the continuous service cycle,the unfiltered fluid enters from the lower chamber, flowing across the candles where filtration will occur. The process water enters the candles through the microgrooves where the contaminants are intercepted, and then flows upwards through the cavities in the wafer candles. The filtered fluid is transported through these cavities into the upper chamber and out to the service connections. As the service cycle continues, the contaminants will cake on to the candle surface, ultimately causing the differential pressure between the two chambers to increase until it reaches a user-defined value, at which point the backwash cycle will be initiated.

Once backwashing is initiated, the clean chamber is pressurized using air, or other gas media, to ranges between 50-120 psi. The drain valve is opened, and the pressurized fluid flows in reverse at high velocity. This creates instantaneous compression of the candle spring, which separates the wafers and breaks up the contaminant cake, cleaning the filter in under a minute using a minimal amount of the clean fluid. Once clean, the service cycle begins again.

All of our filtration systems are individually tailored to meet your specific needs. Filtrex has built a reputation based on performance, reliability and customer satisfaction throughout the world. Contact us today with any questions regarding our products or services.